We are proud to introduce as trusted team to manufacture all types of requirements of Automotive Industries regarding Plastic injection molding. Jai Ambe Enterprises (JAE) isan established manufacturing company based in Pune, INDIA. From its inception

in 2011, JAE has been growing steadily and has become a one-stop-shop for molded components, especially in the field of engineering plastics. JAE is involved in Injection molding.

The strategic completive advantages of Jai Ambe Enterprises (JAE) are its Quality Policy as “Committed to the Manufacturing of Plastic Injection molded Components as per Customers Specifications and to comply with

the requirements of Quality Management System and improve the effectiveness of Quality Management System by monitoring, measuring and continually improving Processes to achieve Quality Products & Quality Objectives”.

- Welcome To Jai Ambe Enterprises

Jai Ambe Enterprises- Plastic Injection Moulding Services in Pune, Pimpri Chinchwad, Bhosari

Jai Ambe Enterprises

OUR VISION

To be a dynamic, innovative and profitable global injection moulding organization for emerging as the preferred supplier and employer, to create value for all stakeholders.

OUR MISSION

Going towards a continuous improvement plan and organizational activities at establishing our company as a pioneer supplier of high quality plastic products, while serving both local and international markets alike.

OUR CORE VALUES

- Honesty and respect

- Teamwork through empowerment

- Consistently high quality

- Health, safety and environment is a way of life

- Sustainability – business, environment and work-life balance

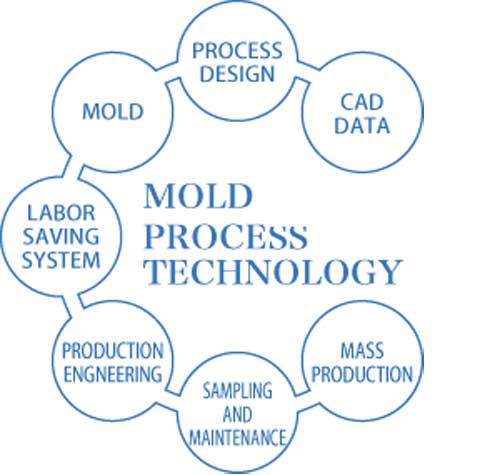

Jai Ambe Enterprises has the capability to manufacture and maintain moulds. Depending on the requirement of the customer we develop moulds with our supporting partner tool room in Pune. Jai Ambe Enterprises manufacturers all of its moulds with channel partners located in MIDC, Bhosari, Pune. To start the process, we require:

- 2D / 3D drawings of the component

- Samples, if available

- Raw Material Specification Sheet

- Annual Quantity

Jai AmbeEnterprises’s channel partners have sophisticated software, like Mold flow Analysis, to design and manufacture moulds. Average time taken to manufacture a multi-cavity mould is 4 weeks. Operational moulds are maintained by a separate team of Tool makers and Fitters.

MANUFACTURING FACILITIES

| EQUIPMENTS | MAKE | CAPACITY | QTY |

|---|---|---|---|

| Horizontal Injection Moulding Machine | TOSHIBA | 80 TON Tie Bar Distance 320 x 320 | 2 |

| Horizontal Injection Moulding Machine | TOSHIBA | 150 TON Tie Bar Distance 460 x 460 | 3 |

| Horizontal Injection Moulding Machine | Asian Plastic | 180 TON Tie Bar Distance 450 x 450 | 1 |

| Horizontal Injection Moulding Machine | TOSHIBA | 200 TON Tie Bar Distance 510 x 510 | 1 |

| Horizontal Injection Moulding Machine | TOSHIBA | 200 TON Tie Bar Distance 510 x 510 | 1 |

| HRC | MOLDMASTER | 6 Zone | 2 |

| MTC | TOSHIBA | 5 LTR (OIL) | 1 |

| CHILLER | Tropicool | 5 TR. | 1 |

Expansion Plan

| EQUIPMENTS | MAKE | CAPACITY | QTY |

|---|---|---|---|

| Horizontal Injection Moulding Machine | SUPER MASTER ( TAIWAN ) | 450 TON | 1 |

| Horizontal Injection Moulding Machine | Dr Boy (Germany) | 22 TON | 1 |

| Horizontal Injection Moulding Machine | TOSHIBA | 250 TON | 1 |

| MTC | TOSHIBA | 5 LTR (OIL) | 1 |

| CHILLER | Tropicool | 5 TR. | 1 |